RESEARCH

Technology Areas

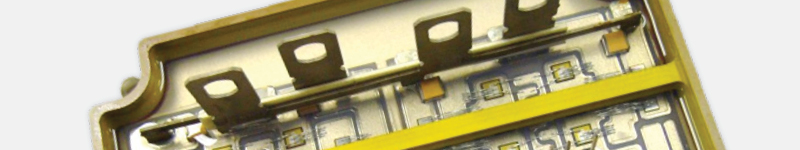

HIGH DENSITY INTEGRATION

The emergence of wide-bandgap semiconductors, such as silicon carbide (SiC) and gallium nitride (GaN) makes it possible to operate power converters at frequencies beyond 5 MHz and temperatures above 200° C. As the switching frequency increases, switching noise shifts to higher frequencies and can be ltered with small passive components — leading to improved power density.

Higher operating temperatures enable not just increased power density, but also the ability for power electronics- based systems to operate in harsh environments, such as military, transportation, and outdoor industrial, and utility systems. High-temperature, high-frequency power electronics systems, however, require more than just better semiconductor devices. Designers must also consider materials, gate drives, controller, passive components, packaging, and cooling.

The scope of work includes

- High-temperature integration — Reliable direct-bond-metal substrate; different die-attach technologies for thermo-mechanical reliability; high-temperature encapsulants for power electronics modules.

- Components: Characterization and modeling of wide-bandgap semiconductor devices; high-frequency magnetics and capacitors.

- Module-level integration: High-temperature packaging of power modules, including gate drives, sensors, and protection.

- System-level integration: High-density power supplies on a chip; high-temperature control components and system integration; integrated packaging of LEDs and drivers.

CPES research in this area follows two coupled paths, leveraging the availability of wide-bandgap power semiconductors and high-temperature passive components and ancillary functions. Both switching frequency and maximum component temperatures are being pushed as high as component technologies, thermal management, and reliability permit.